|

|

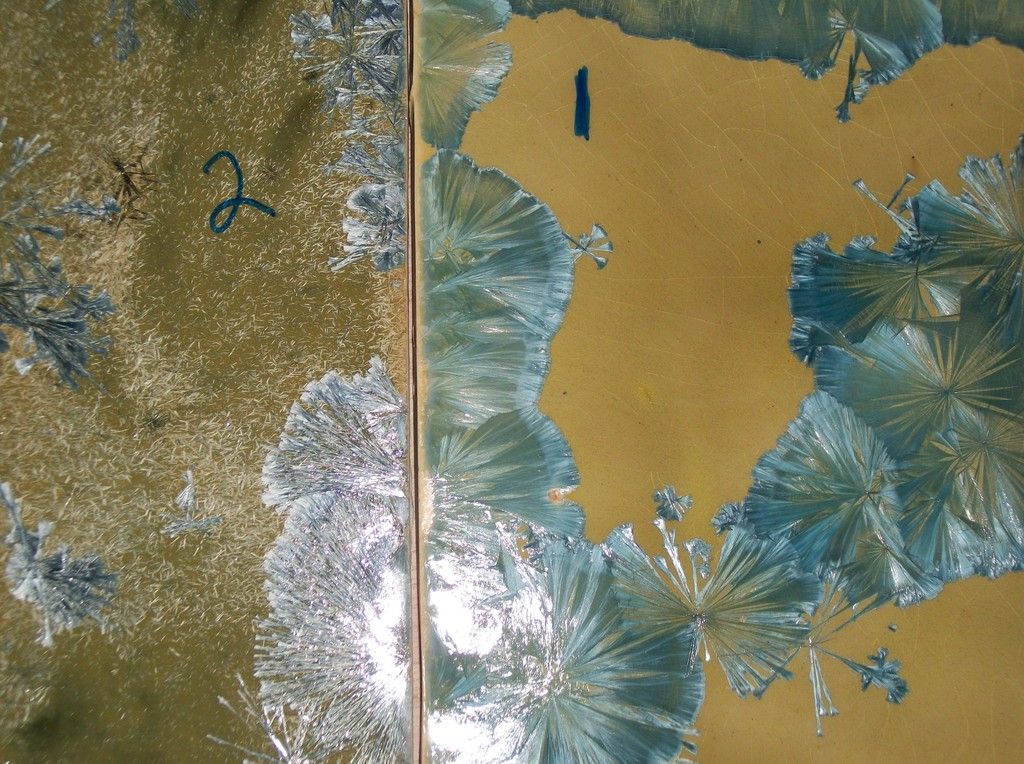

Post by tileman2 on Jan 8, 2016 18:21:48 GMT -6

Jim: Here is a stumper for ya. Same kiln, same shelf, same glaze batch cut in half and applied to two test tiles. Tile 1 I added .50% of a modifier-- name that modifier? Anyone can play the - name that modifier?  NOTE: Cadmium is toxic like lead- should not handle it unless you have a respirator and other equipment to do so safely. This warning added for the newbies who may not know about proper handling. Tom - Not really considered a colorant- but a modifier. Yes, I pulled it out of the kiln at 350F- so sue me. |

|

|

|

Post by jfox on Jan 8, 2016 20:52:32 GMT -6

Sn?

|

|

|

|

Post by tileman2 on Jan 8, 2016 21:06:26 GMT -6

I would have made the same guess- but Cadmium. Certainly adds to growth as well. Surprised by the results actually.

Base formula for both 10% rutile / .50% Co Carb

|

|

|

|

Post by mohawkpiper on Jan 15, 2016 22:23:34 GMT -6

Tom,

I think the neutral brown colors on the tiles that you posted look very nice there in that kitchen. I would have picked the same I think. Good job it looks great.

|

|

|

|

Post by tileman2 on Feb 2, 2016 17:59:23 GMT -6

Ty Greg- just now realized you posted a response. Going to be doing a shower stall this spring with geometric tile. Jim: I have been testing Cadmium in various combinations: seems it is very reactive to TiO2. In tests with regular colorants with low percentages of TiO2 is does enhance color, but very little besides that. However, when used with Rutile or Ilimenite, or high percentages of TiO2 the effects are very dramatic. I ran this test over the weekend: both tiles have 4% rutile, 0.50% NiOx, and 0.25% TiO2. Tile 1 is the usual result from this colorant combination- Tile 2 has 1% cadmium.  Cannot explain why it reacts so wildly with TiO2, but it does. Hard to believe these two tiles have the exact same colorants. The green/blue in tile 2 reminds me of the color produced from copper reduction. The other oddity, the usual crystal formed from a nucleation site, and then a second courser crystal grew on top of it. Do not believe I have seen that before. The other point of interest: the crystals are very glossy as usual, but the field has almost a satin type finish/look. Look closely at the top of tile 2: can see the deeper green crystal on bottom, and the courser mint green crystal growing over it. Weird stuff. Tom |

|

|

|

Post by jfox on Feb 2, 2016 22:16:33 GMT -6

both of those look pretty familiar to me. at cone 10 ,i'm leary of raw cadmium ,ive read some horror storys

|

|

|

|

Post by tileman2 on Feb 3, 2016 19:46:58 GMT -6

Jim:

Cadmium ranks right up there with lead- have to observe safety practices when using it. Everyone using yellow zinc is being exposed to trace levels of cadmium and lead- naturally occurring. Just blows my mind that it can have such a dramatic effect.

In another note: might have to put off retirement for awhile. Got a phone call today, builder got into trouble building a 140 unit retirement center. Banks want to know if I would take it over and finish it. They made a mafia offer- one that is very hard to refuse.

Tom

|

|

|

|

Post by tileman2 on Mar 17, 2016 20:58:29 GMT -6

Came in from the NCECA convention in KC last night. If you need to buy larger equipment purchases: these are the times to do it. All of the clay, kiln and equipment makers are there-wheeling and dealing. Paragon offered me several of their larger kilns for nearly 1/2 price. Clay makers offering big discounts on 500lb lots to get you to try their products. Lots of ceramic professors from various colleges around the country: interesting show overall. NCECA 2017 is in Portland Oregon.

Went out there primarily to meet with Ron Roy, one of the more well known clay chemists. Had private meetings with him Monday and Tuesday to discuss clay body formulations for specific use with crystalline glaze. Now you know what I will be doing this summer, in addition to a few other specialty ideas I have been working on. Onward!!

Tom

|

|

|

|

Post by tileman2 on Mar 20, 2016 19:27:28 GMT -6

Question:

Obviously I am going to formulate a clay body for flat work: being a tile guy. However, would also like to formulate a body for throwing. So the question is: what is your favorite/preferred grog size?

Tom

|

|

|

|

Post by jfox on Mar 21, 2016 8:39:10 GMT -6

in the 60's and 70 i used 30 # sand (soldate 30) hard on the fingers but easy to throw .in the 80's went to 60 then a glass sand thats 60 to a 100

now i used 60 or 100 mullite.what was the take away from tour meeting with Roy,just remembered i used to use Molichite

its similar to mullite but also has fused silica in it

|

|

|

|

Post by tileman2 on Mar 21, 2016 10:25:01 GMT -6

Jim:

I have been using molochite for years to kill the plasticity in my clay. I ordered 70F grog (mullite) yesterday. My take away from Ron Roy was that clay body formulation is a whole lot easier than glaze compositions. Had always thought that sodium or potassium feldspars were the fluxes of choice or required. Learned there are numerous fluxes you can use. including zinc and frit. Surprised me actually, who knew?

Also learned that free silica and crystobalite formation in cone 10 clays are the primary causes of slumping and dunting.

Tom

|

|

|

|

Post by tileman2 on Mar 21, 2016 10:35:03 GMT -6

My latest attempt at a cone 6 run free glaze- getting closer. There is no glaze run off on the sides or back.  Tom |

|

|

|

Post by evan cornish-keefe on Mar 21, 2016 12:27:21 GMT -6

Hey Tom,

I haven't got very far into testing clay bodies yet, but I've been learning a lot from the book "The Ceramic Process" by Anton Reijnders.

It gives some great info about different types of clay minerals that compose naturally occuring clays, differences between Kaolinite, Illite and Montmorillonite etc, and the effect those have on plasticity, shrinkage, green strength....

The book also describes how to analyze the grain size by running the dried clay body through consecutively smaller sieves. It lists an optimal particle packing. The difference between the clay body and the optimal grain size serves as a guide for how much grog/molochite of each mesh to use. It sounds like the particle packing is especially important for large tiles.

Sounds like as much of a headache as a crystalline glaze that doesn't run, hope you have better luck with that than I did.

Also, my understanding is that a body that slumps has excessive glass formation (and is over fired), while a body that has excess free silica or cristobalite is under fired and prone to dunting.... Does that sound right?

|

|

|

|

Post by jfox on Mar 21, 2016 13:07:09 GMT -6

my experience with no run crystal glaze has been if it didnt run this time there is all ways next time

|

|

|

|

Post by tileman2 on Mar 21, 2016 21:06:44 GMT -6

Evan:

Grain size is one of the main differences between stoneware and porcelain bodies. Stoneware utilizes course grained ball clay primarily, and porcelain is medium; but mostly fine. Kaolin is a much purer material than ball clay. The ball clays used for stoneware have a fair amount of iron and then magnesium: where stoneware gets its color from. Kaolin has very little, and a few like New Zealand have none. Actually New Zealand is the purest clay available: reason it is favored in high quality porcelain and is thought to help crystal growth. Most stonewares and porcelains will tolerate being over-fired by a cone, some slightly more. Earthernware has a very low tolerance for being over-fired.

Over-fluxing is a problem no matter what cone rating the clay has, but free silica and crystobalite formation is never a problem until you fire well above cone 6. Too much flux weakens the body because of fluidity, and free silica and crystobalite likewise weakens the body. I got the basics down, still have alot of learning to do myself.

Tom

|

|