|

|

Post by tileman2 on Apr 17, 2016 20:15:22 GMT -6

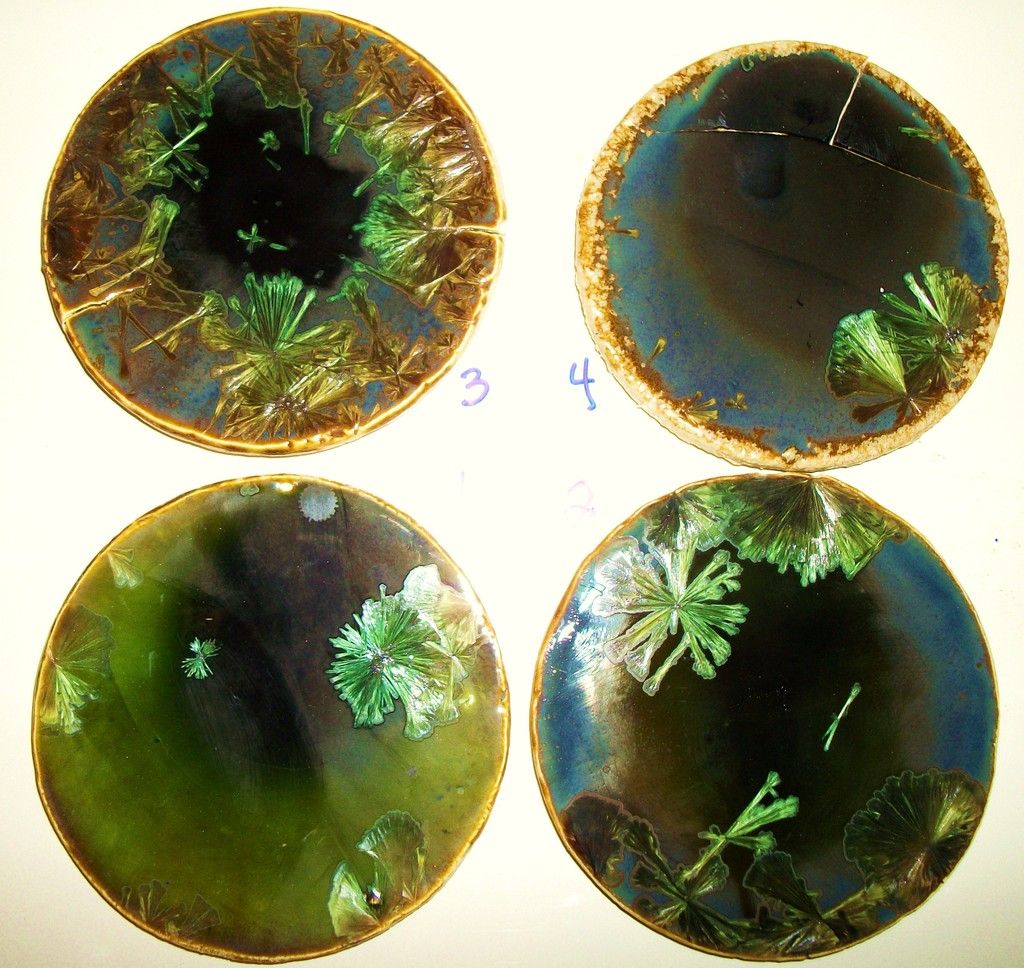

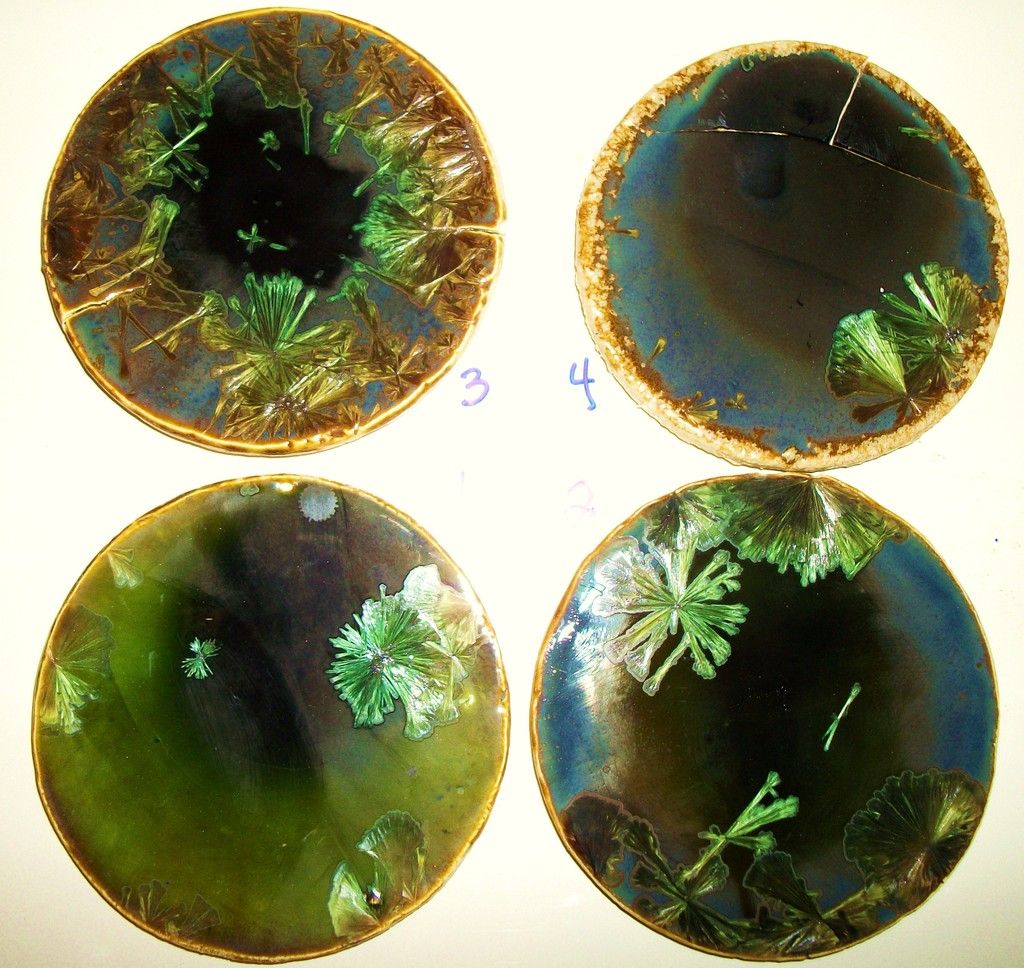

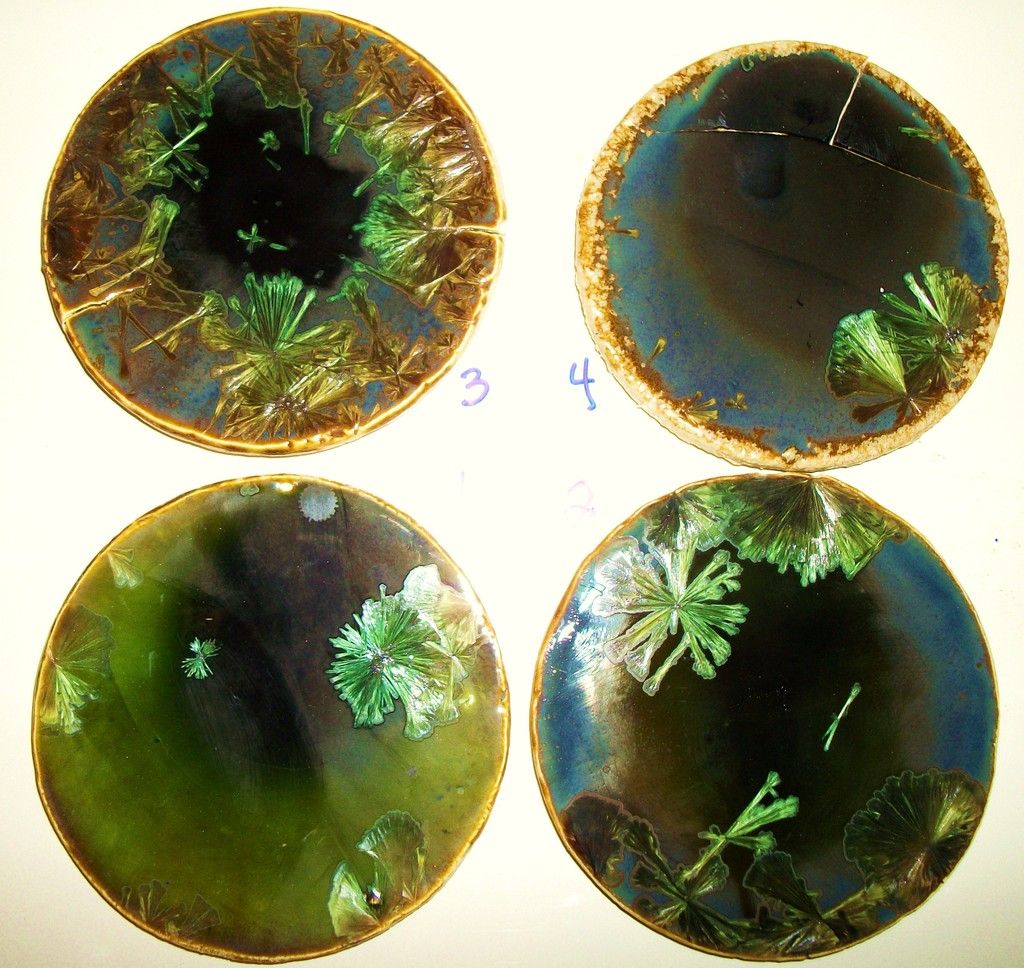

After meeting with Ron Roy in KC a few weeks back I have been testing custom clay bodies. I have long felt that the fluxes used affected crystal development on various level/s. So I ran a test of three custom blended clays against a standard Laguna cone 6 porcelain. All tiles fired on the same shelf, same kiln, and same glaze batch applied. 3% Copper black / 3% FE-iron.  Sorry- the #1 & 2 does not show up in the picture.. no idea why. Tile 1 (Lower left hand corner) Standard Laguna Cone 6 clay- notice how green the field is. Tile 2: (Lower right hand corner). Fluxes were formulated in equal amounts of sodium and potassium. The field color changed from green to blue edges with green center. Crystal development also changed. Tile 3: Sodium was reduced to 0.18% of batch weight/ mostly potassium. The field is mostly blue, with very little green. Crystal development also changed, and crystals grew roughly 20% larger. Tile 4: Sodium is 25% and potassium is 75%. Crystal development is larger and color changes are noted. It is known that potassium can be used in some percentages to affect color/s. However, by reducing sodium content in the clay crystals grow slightly larger. When sodium is almost completely removed: unexpected colors are produced such as the bronzing effect in tile 3. However, when potassium levels get too high like in tile 4: off gassing becomes an issue. Nep SY is becoming a flux of choice in the clay biz: which also increases the sodium levels in the clay. So in some cases it may not be the glaze formula affecting crystal development, but rather the clay itself. Note: these conditions exist mostly with cone 6 firings, and are less noticeable in cone 10 because the additional heat reduces the effects of sodium. Tom Edit: sodium and potassium levels also effected the type of crystals that grew. All four were fired at the same time, with the same ramp hold temp. |

|

|

|

Post by hollymckeen on Jun 28, 2016 12:34:30 GMT -6

Late in reply here, but regarding posts on the first pages about rough crystals, my experience has been that "felting" or these rough crystals is about application in some instances, and certainly glaze/body match-up, but also has to do with how precise the firing is controlled, both in reaching top temp and in coming down to first hold. Also, some frits are more prone to it than others. I almost never get felting with 3110 glazes, it is very forgiving, but 413 needs much more care and attention. I once kept losing large silver nitrate platters to it which was such a p/o, given the cost of the silver alone, and after trying everything else, I finally changed my elements (which were getting close to needing it, but not there yet) - that got my push to top temp faster and more exact, and the platters came out perfect - the felting stopped altogether. Perhaps this tidbit might help.

I just smash em when "felted" or with rough crystals. Sometimes a refire with a 3110 with cobalt over will smooth them out. Sometimes not.

|

|

|

|

Post by tileman2 on Jul 11, 2016 20:47:32 GMT -6

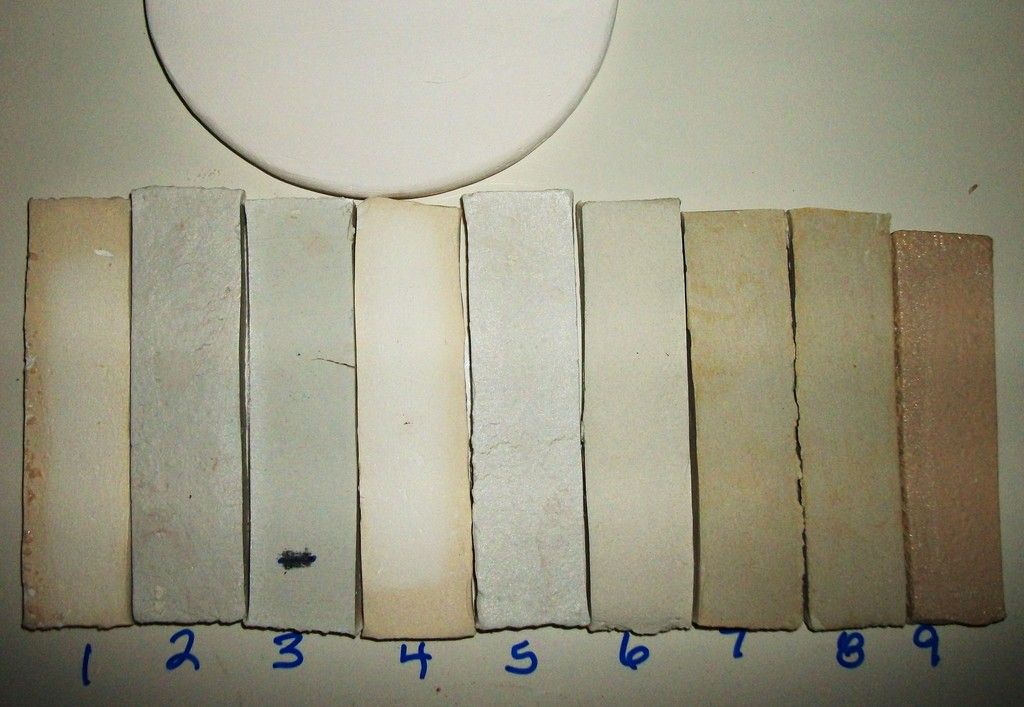

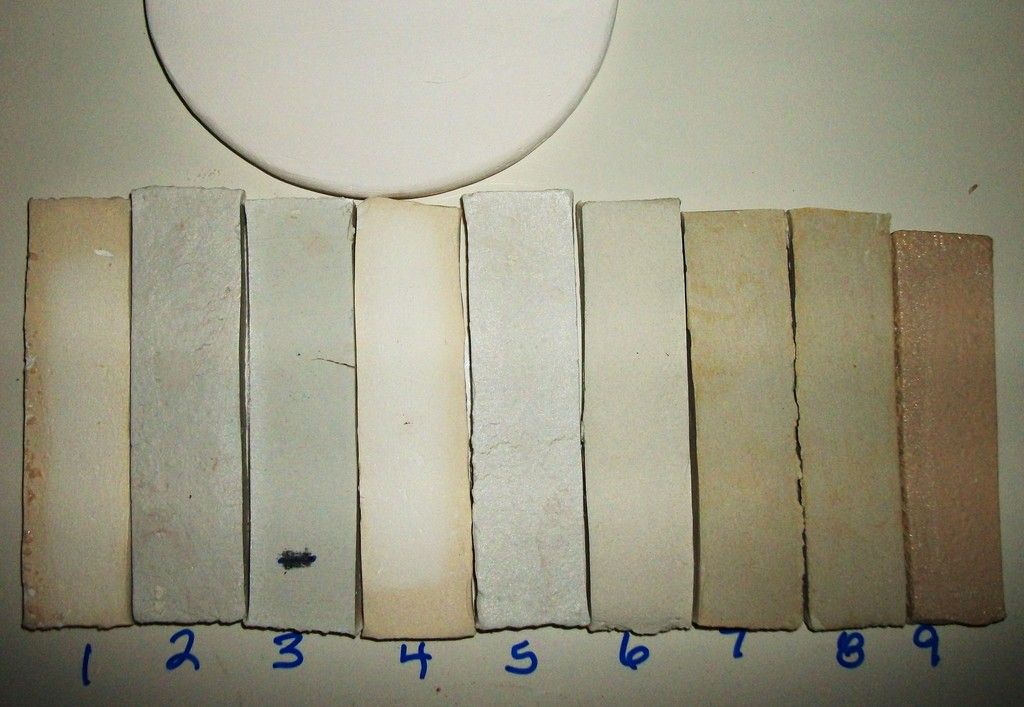

Have spent the last three months compiling formula limits for porcelain clay. The following is a chart you can use to compare your fired ware to the test bars. It will give you some general sense of the composition of your clay. Glaze can leach iron, magnesium and titanium; just as it can leach alumina. Make a simple test bar/tile and fire to cone unglazed to check.  Bar 1 MGO 0.33 FE 0.32 Bar 2 MGO 0.89 FE 0.36 Bar 3 MGO 0.78 FE 0.42 Bar 4 MGO 0.42 FE 0.36 Bar 5 MGO 0.63 FE 0.32 Bar 6 MGO 0.49 FE 0.40 Bar 7 MGO 0.36 FE 0.86 Bar 8 MGO 0.42 FE 0.74 Bar 9 MGO 0.97 FE 0.91 TiO2 3.77 Control Tile- top MGO 0.18 FE 0.32 Tom Edit Note: high levels of TiO2 produce almonds. High levels of MGO produce grays. High Fe produces tans/brownish. |

|

|

|

Post by jfox on Jul 12, 2016 7:42:43 GMT -6

Tom

I think I remember after you met Roy ,you saying your takeaway was its easy to throw together a clay body but my experience has been otherwise ,the search for an "Ideal" Clay is much like the search for The Holy Grail. its always a trade off .a tile body is one thing,

a throwing body is even more challenging.so many variables, compounded by the fact that the constants (the minerals) keep changing

|

|

|

|

Post by tileman2 on Jul 12, 2016 17:10:15 GMT -6

Actually I said that blending clay is easier than glaze because there are not as many parameters. The one thing I did notice rather quickly that there was no set formula limits for clay, as there is with glaze. So I took the time to test about 100 small batches (100 grams) to set formula limits for iron, titanium, and magnesium. Also set limits for fluxes, and tested several blends as well. I will be using technical grade kaolins instead of pottery market clay, not pure or consistent enough. I have two tile formulas that look promising: both require no work at all. Just roll it, cut it, and throw it into the kiln when dry. Do not have to weight, flip, or mess with it. One produces good crystal results, the other needs fine tuned a bit.

Tom

|

|

|

|

Post by hollymckeen on Jul 21, 2016 14:09:03 GMT -6

Jim, so right. I have now tried 8 different porcelain bodies, comparing all aspects of how the crystals like them, how they hold up at cone 11 coming over and how they are to work with. How the crystals like the body is only one aspect, and throwability and handling are very big for me. Most of the issues that have been deal breakers stem from how a porcelain will throw, trim and stand up in the firing. If I get great crystals from it to boot, am super happy. Best body yet for crystals and standing up to higher temps is Suzuki from SPS, but it doesn't throw well... Still searching for my Holy Grail of porcelains.

|

|

|

|

Post by tileman2 on Jul 26, 2016 10:50:03 GMT -6

Fired my custom clay body yesterday to see how crystals do. Top tile: cone 10 iron with 2.5 hold. 1 5/8" crystals. Bottom tile: (copper) cone 6 with 2.5 hour hold. 2 1/4" crystals.  Getting closer- clay does make a difference. Need to formulate for cone 10, curious. Tom |

|

imtrying

New Member

hello im a new member from Belgium. on cristallines im a beginner, web: www.jeanszostek.be

hello im a new member from Belgium. on cristallines im a beginner, web: www.jeanszostek.be

Posts: 3

|

Post by imtrying on Jan 25, 2017 8:03:52 GMT -6

Hi, Everybody (in some books  ) tells that at cone 6 it is impossible to grow big crystals. But I think this is an "urban legend"... I tried fire at ^6 and this is what I get with maximum 1222 C (2232F) and 3h of hold:  Same glaze on different shape:  The biggest problem is that crystals are very rough, especially where there is more glaze thickness. P.S. I like this green/turquoise very much:) More photos please. |

|

|

|

Post by tileman2 on Aug 6, 2018 18:49:03 GMT -6

Cone 5 (2222F) to be exact. Single fired. Yes, I chipped the rim handling green ware- oppss! Total soak 3.2 hours. The glaze recipe is simple/basic, it is the custom clay recipe producing the result. ( 3.25" maximum crystal) notice the empty catcher?  I gave up trying to post pictures, here is a link. community.ceramicartsdaily.org/gallery/image/10103-cone-5-crystalline-glaze/Tom |

|

|

|

Post by frederi on Aug 8, 2018 17:37:13 GMT -6

Tom, Glad to see you posting recent work.

I'm expecting that for the clay to be involved in the glaze "behavior" the thickness is relatively thin.

Later I realized (prompted by your note) there was no runoff so perhaps it is a thin glaze. Large crystals from top to bottom suggest uniform thickness.

As an aside I did some experiments with lithium only as the flux and got large crystals in a thinly applied glaze.

Cheers,

Gordon

|

|

|

|

Post by tileman2 on Aug 8, 2018 21:27:09 GMT -6

Gordon:

The clay is very much involved. Glaze application is 0.40 grams per square inch. 3 even coats- sprayed.

Couple of years back I ran trials: 50% grolleg, 35% spodumene, 15% silica. I noticed the growth patterns, actually had to fight over-population. I ran several at 2175 to 2190F peak, with sporadic development., some improvement using zincite instead of sphalerite. Going to revisit that at some point in the future, came to the conclusion that lithium carb additions in the glaze were vaporizing the metallic zinc. Zincite is a rather powerful flux on its own. So the general belief about hyper fluidity of the glaze appears to be a myth at this point. Additional note: no crazing issues; but then again the COE of the body is above .6.50. Ron will run a dialometer on it later.

T

|

|

) tells that at cone 6 it is impossible to grow big crystals. But I think this is an "urban legend"...

) tells that at cone 6 it is impossible to grow big crystals. But I think this is an "urban legend"...